Improving Pipeline Construction Quality

Background:

Each year the pipeline industry repairs, replaces, and adds to the vast pipeline network serving the needs of the United States of America. PHMSA regulates this activity via construction inspections, investigations of first year in-service failures, as well as investigations of industry reported material and construction issues. PHMSA's overall mission is to provide safety and the best way to improve safety, as identified by these efforts, can be summarized into one word: Quality.

What's Been Done:

Over the years, efforts to improve pipeline construction quality have been iterated upon and have evolved. In the beginning, it started as conducting industry workshops and issuing advisory bulletins (ADB-09-01 and ABD-10-03) to better disseminate lessons learned and best practices as well as relay PHMSA's expectations for the industry. This evolved into a concept called Quality Action Plans (QAPs) which essentially was a checklist co-developed by industry to help improve the quality of pipeline construction. Today, PHMSA advocates for the use of a Quality Management System (QMS).

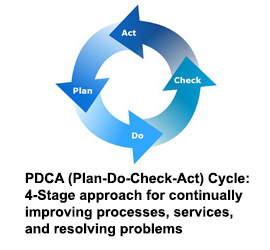

You can think of a QMS as a detailed system of checks and balances. The main concept of a QMS is a repeating cycle of steps; "Plan⇥Do⇥Check⇥Act".

One widely accepted QMS is International Organization for Standardization 9001 (ISO 9001). The American Petroleum Institute (API) also developed Specifications Q1 and Q2 which deal more directly with the pipeline industry. However, ISO 9001 and neither API Specifications Q1 or Q2 directly relate to pipeline construction. As a result, PHMSA sponsored a research and development project titled "Improving Quality Management Systems (QMS) for Pipeline Construction Activities". Det Norske Veritas (U.S.A.), Inc. (DNV GL) was awarded the contract and over the course of 16 months developed the document linked below.

View the Final Report from DNV

This report provides a QMS framework to assist pipeline companies in their development of a company specific QMS. The report applies to operators of natural gas and liquids transmission pipelines, as well as natural gas distribution lines.

Prior to the completion and publication of DNV's report, the Interstate Natural Gas Association of America (INGAA) published a report titled “Guidelines for Practical Implementation of a Construction Quality Management System". Finally, API published RP 1177 titled "Recommended Practice for Steel Pipeline Construction Quality Management Systems" after the DNV report was published.

Future Work:

Many pipeline operators and companies already use a QMS or at the very least a framework of a QMS, however it's use it not specifically required by current regulations. The next step in this process is to add to or augment current pipeline construction regulations to require the use of a QMS or something that provides similar outcomes.

Improving Pipeline Construction Safety

The Pipeline Safety Management System (SMS) industry standard API RP 1173 was published in July 2015 and developed by API with input from PHMSA, NTSB, states, and industry representatives. This standard's purpose is to aid pipeline operators in making a basis for developing comprehensive, process-oriented approaches to safety with an emphasis on continued assessment and improvement.

The overall goal is to improve the effectiveness of risk management while allowing continued improvement of pipeline safety by operators. SMS's intent is to provide a systematic method in identifying hazardous threats and to control these perils while maintaining assured and effective risk controls. At this time, PHMSA has not incorporated the SMS standard into its regulations and inspection protocol.