LNG Plant Requirements: Frequently Asked Questions

The below FAQ list may provide an acceptable solutions which PHMSA has carefully evaluated. We realize there may be other acceptable solutions, which we are open to consider. Other proposals require substantial technical justification to insure that any alternative approach provides an equivalent or higher level of safety. As this requires a case-by-case engineering evaluation, this may increase the design spill review time. A historical record of PHMSA's FAQs are compiled in PHMSA-LNG-FAQs-2014-2023.pdf.

G) General

G1. The abundant supply of domestic natural gas is driving development of new ways to use, process, and transport LNG. Can PHMSA provide guidance as to which LNG facilities are regulated under 49 CFR Part 193?

The Pipeline Safety Statute codified in 49 U.S. Code § 60101, et seq, directs US DOT to establish and enforce standards for liquefied natural gas pipeline facilities. An LNG facility is a gas pipeline facility used for converting, transporting or storing liquefied natural gas.

Many LNG facilities are subject to the regulatory and enforcement authority of the Department of Transportation through PHMSA. A simple but not complete test to determine if an LNG facility is regulated under 49 CFR Part 193 is to identify both the source and the consumer of the LNG. The facility is regulated under 49 CFR Part 193 if the LNG facility either receives from or delivers to a 49 CFR Part 192 pipeline.

49 CFR Part 193 does not apply to:

- LNG facilities used by ultimate consumers of LNG or natural gas.

- LNG facilities used in the course of natural gas treatment or hydrocarbon extraction that do not store LNG.

- In marine cargo transfer systems and associated facilities, any matter other than siting pertaining to the system or facilities between the marine vessel and the last manifold (or, in the absence of a manifold, the last valve) located immediately before a storage tank.

- Any LNG facility located in navigable waters (as defined in Section 3(8) of the Federal Power Act (16 U.S.C. 796(8)).

Operators should assume an LNG facility used in the transportation of gas by a 49 CFR Part 192 pipeline is regulated under 49 CFR Part 193 unless specifically exempted in Section 193.2001(b). LNG facilities may be regulated by PHMSA even though they are not regulated by the FERC. The 'ultimate consumer' provision provides a very limited exemption from 49 CFR Part 193. PHMSA interpretation # PI-10-0025 provides guidance. Here is an excerpt:

During the rulemaking that led to the adoption of § 193.2001(b)(1), OPS explained that the intent of that provision was to create an exception for "an LNG facility used by the ultimate consumer of the product". Likewise, in responding to a series of questions from a congressional committee, OPS stated that the exception in § 193.2001(b)(1), was designed for "small" facilities which are "generally located in industrial plants ... [to] serve as a supply of energy or feedstock for the plant." Unlike these examples, the Maine LMF facilities would be used to produce LNG for sale and distribution by truck, not solely for onsite consumption. Therefore, OPS concludes that your client's facilities would not qualify for the end-user exception in § 193.2001(b)(1).

Follow this link for a map of LNG Plants regulated under 49 CFR Part 193 (except mobile and temporary). This document illustrates examples of LNG facilities that are or are not regulated under 49 CFR Part193.

G2. What agency or agencies have regulatory authority over the siting of LNG facilities?

There are more than 110 liquefied natural gas (LNG) facilities operating in the U.S. performing a variety of services. Most of these facilities store LNG for "peak shaving," where the LNG is vaporized and transported in gas transmission or gas distribution pipelines for periods of peak demand. There is significant growth in the number of facilities producing LNG as a transportation vehicle fuel for trucks, buses, trains, and ships. Depending on the location and use, several Federal agencies and State utility regulatory agencies may regulate an LNG facility.

For LNG import and export facilities located onshore, three Federal agencies share oversight for safety and security: the Federal Energy Regulatory Commission (FERC), the U.S. Coast Guard, and the U.S. Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA). Under Section 3 of the Natural Gas Act of 1938, FERC is responsible for authorizing the siting and construction of onshore and near-shore LNG import or export facilities. Under Section 7 of the Natural Gas Act of 1938, FERC also issues certificates of public convenience and necessity for LNG facilities engaged in interstate natural gas transportation by pipeline. As required by the National Environmental Policy Act (NEPA), FERC prepares NEPA analyses for proposed LNG facilities under its jurisdiction. The Coast Guard has authority over the safety of LNG vessels and the marine transfer area, conducting Waterway Suitability Assessments to address navigation safety and port security issues associated with LNG ship traffic. PHMSA has authority to establish and enforce safety standards for onshore LNG facilities.

PHMSA's regulations for LNG facilities appear in Title 49, Part 193 of the Code of Federal Regulations (CFR). LNG facility applicants, when applying to FERC, are required to identify how their proposed facility would meet the siting requirements of 49 CFR Part 193. FERC consults with its cooperating agencies, including PHMSA, as needed. Once FERC approves a project and the applicant moves forward in the process, PHMSA inspects sites during and after construction, and during facility operation, and is responsible for taking enforcement action under Part 193 if necessary.

G3. As an operator, how do I submit an application to install a FERC regulated LNG facility?

The FERC is responsible for authorizing the siting and construction of onshore and near-shore LNG import or export facilities and LNG facilities engaged in interstate natural gas transportation by pipeline. As an operator of one of these types of facilities, you must coordinate with the FERC in the development of the Resource Reports required for the FERC application process. Information on Resource Reports 11 & 13, which deals with the engineering detail of the LNG facility, can be found in 18 CFR 380.12 (m) & (o).

G4. What types of LNG facilities require information submittal?

If an LNG facility requires FERC review and siting approval, PHMSA as a cooperating agency will require detailed information as described in these FAQs. Please refer to Subpart A of Part 193 for scope and applicability of PHMSA's regulations. There are regulations in Part 193 pertaining to siting, design, construction, equipment, maintenance, personnel qualifications and training, fire protection, and security. If the operator has questions or needs further guidance on the applicability of Part 193 to the facility in question, then the operator may contact PHMSA headquarters or the PHMSA Regional Offices. PHMSA's regional contact information is located here, or you may contact PHMSA's Director of Engineering as noted below under FAQ #G6.

G5. Does PHMSA have an application or permitting process for new or modified LNG facilities that are subject to the jurisdiction of Part 193 but does not require FERC review?

PHMSA does not require an application process and does not have authority for permitting LNG facilities. PHMSA requires LNG operators submit information to the National Registry of Pipeline and LNG Operators database 60 days prior to commencing construction. See FAQ #G10 below for more information.

LNG operators may be required to submit an application to the Federal Energy Regulatory Commission (FERC) or the appropriate state agency. Operators must notify the State Pipeline Safety Agencies at least 2 weeks prior to the installation of portable LNG facilities and provide information prescribed in §193.2019 (b).

Determining how to comply with 49 CFR 193 is the responsibility of the operator. PHMSA is available to answer your questions. Please contact the Engineering and Research Division at (202) 366-4433 or by email PHMSALNGTeams@dot.gov.

G6. Since PHMSA is a cooperating agency in the FERC siting process, do I need to provide anything directly to PHMSA in order to help expedite the application process?

Yes. If a facility is subject to Part 193 (see reply to FAQ #G3 above), then in order for PHMSA to perform an in-depth review and analysis, you should copy and forward specific items for evaluation. You should send all application materials directly to FERC, but you should also submit to PHMSA hard and digital copies of the documents noted in these FAQs to aid PHMSA in its review. Review of your application will be delayed unless you promptly submit to PHMSA substantially complete application materials. Please also be aware that PHMSA will need detailed materials without any redaction, regardless of security sensitive or proprietary information, in order to conduct a full review. If you believe your materials are security sensitive or proprietary in any way, please mark them accordingly.

Materials noted below should be addressed to:

U.S. Department of Transportation

Pipeline & Hazardous Materials Safety Administration

Max Kieba – Director

Engineering and Research Division

Room E22-329

1200 New Jersey Avenue, SE

Washington, DC 20590

Telephone: (202) 493-0595

Email: Max.Kieba@dot.gov

G7. What specific items should be sent to PHMSA?

The applicant should submit a Design Spill Package directly to PHMSA to aid in the review process. Detailed engineering materials are required as part of the Design Spill Package.

The Design Spill Package should include:

- Project description, background, purpose and details describing the proposed facility;

- Hazard reports, including any attachments and referenced reports;

- Facility location map(s), topography map(s), and site aerial photography;

- Engineering drawings including an overall plot plan showing the project’s property boundary and unit plot plans for each process area or system showing the location and elevation of major equipment. Each area and piece of equipment should be clearly labeled. The unit plot plans should be detailed enough to allow for measurement of distances between various components with a reasonable degree of accuracy. The smallest scale submitted should be no smaller than 1-inch to 100-feet (1:1200);

- Piping and instrument drawings (P&ID);

- Process Flow Diagrams (PFD);

- Heat and Material Balance Sheets (H&MB);

- Piping Inventory Table;

- Pump and compressor curves for pumps and compressors used for hazardous fluid service (as available);

- Sketch on plot plan showing expected locations and elevations of major potential single accidental leakage sources;

- Dimensions, capacities, and thermal properties for any impoundments associated with this project;

- Design details for mitigation measures, including vapor barriers and pipe-in-pipe systems; and

- The summary report of all input and output parameters for computer program simulations (i.e., PHAST) should be included.

-

Note: The summary report will provide the design spill criteria and screening assessment that was used.

If additional information is required, PHMSA will work with the applicant on additional information submittals.

G8. After I submit information to PHMSA, how long will the review process take?

The duration of the review process varies. There are a variety of factors which influence the timeline for review and approval, including the volume of previously submitted applications, where the applicant is in the siting process, and the completeness of the submitted information. PHMSA will acknowledge receipt of the application and will begin the review process. PHMSA will contact the applicant during the review process to resolve any outstanding needs or questions.

G9. After I submit the required information to PHMSA, what information do I need to file on the FERC docket?

For those projects under FERC jurisdiction, all information submitted to PHMSA should be filed on the FERC docket. PHMSA will work with the applicant to review the information. If revisions or edits are necessary, the applicant will be instructed to file an addendum to the FERC docket.

G10. A FERC regulation (18 CFR § 385.2201) prohibits off-the-record communications in a contested, on-the-record proceeding. The rule is designed to limit communications between a "decisional employee" at FERC and persons outside the Commission. How do FERC's restrictions on ex parte communication affect PHMSA's communications with LNG project applicants?

The purpose of the rule is to ensure the integrity and fairness of the Commission's decisional process, and to prevent off-the-record communications relative to the merits of a Commission proceeding between FERC decisional employees and entities outside of the Commission. Generally, communications regarding Part 193 compliance between PHMSA and a party before the Commission do not violate FERC's ex parte rules. However, PHMSA takes care to not act as a conduit for otherwise unpermitted communications. Some communication between PHMSA and a facility applicant is expected, but PHMSA restricts those communications to matters that FERC has explicitly referred to PHMSA. In accordance with the FERC's public disclosure requirements and FERC's responsibilities under its ex parte regulations, PHMSA, as a cooperating agency, cannot release pre decisional information related to the NEPA analysis (such as working drafts of NEPA documents and PHMSA comments on those working drafts).

If PHMSA needs additional information from an applicant to resolve a matter that FERC has referred to us, PHMSA will advise FERC and the applicant of what additional information is needed and request that it be submitted to FERC's docket.

G11. How do operators notify PHMSA that construction, upgrade, or refurbishment of an LNG facility will be commencing?

New operators must first obtain an Operator Identification Number (OPID). To obtain on OPID, an operator must complete an OPID Assignment Request DOT Form PHMSA F 1000.1 th rough the National Registry of Pipeline and LNG Operators in accordance with §191.22(a).

rough the National Registry of Pipeline and LNG Operators in accordance with §191.22(a).

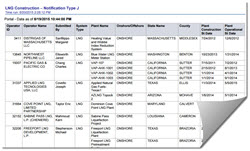

Each operator of an LNG plant or LNG facility is required to submit notification of specified events to PHMSA in accordance with §191.22(c). Operators must use the Operator Registry Notification (Form PHMSA F 1000.2) to report new construction, asset-changing or program-changing events associated with LNG facilities. Within Form PHMSA F 1000.2, operators planning to begin new construction, refurbishment or an upgrade project, regardless of cost, select a Type J – New Construction Notification.

Construction notifications are required to be submitted 60 days prior to the "event." On September 12, 2014, PHMSA published an Advisory Bulletin describing the activities that constitute the "event" of construction, which determines the due date for the notification. The types of construction events that would initiate a notification submittal include material purchasing and manufacturing, right-of-way acquisition, construction equipment move-in activities, onsite or offsite fabrications, or right-of-way clearing, grading and ditching.

Click here to view LNG Construction Report – Notification Type J in a new window.

Note that operators have requirements for the reporting of incidents, safety-related conditions, and annual pipeline summary data in accordance with §191.1 and to submit mapping data to the National Pipeline Mapping System (NPMS) in accordance with §191.7. Requests for OPID, construction notifications, and reporting must be made online via the PHMSA portal, using assigned user name and password, unless an alternate method is approved. Copies of the forms and instructions for PHMSA F 7100.3 (Incident Report) and PHMSA F 7100.3-1 (Annual Report) can be found on the Pipeline Safety Community Web Page at https://www.phmsa.dot.gov/forms/pipeline-forms. Contact the PHMSA Information Resources Manager at (202) 366-8075 if you have questions. For information about making an NPMS submission, see https://www.npms.phmsa.dot.gov/PipelineOperator.aspx.

G12.What are the siting requirements for small LNG facilities that have an aggregate storage capacity of 70,000 gallons or less on one site?

The writer asks, "Part 193 has requirements for thermal radiation exclusion and vapor-gas dispersion exclusion zones that are required for each LNG container and transfer system, but NFPA 59A, 2001 edition has Table 2.2.4.1 Distances from Impoundment Areas to Buildings and Property Lines for small LNG facilities with total onsite storage capacity of 70,000 gallons LNG or less. Does NFPA 59A, 2001 edition, Chapter 2, Plant Siting and Layout, paragraph 2.2.3.7 which allows use of Table 2.2.4.1 'Distances from Impoundment Areas to Buildings and Property Lines' conflict with Part 193 Subpart B – Siting Requirements?"

Part 193 siting requirements include the determination of exclusion zones, areas in which the operator or a government agency legally controls all activities. The exclusion zones are determined by complying with §193.2057 Thermal radiation protection and §193.2059 Flammable vapor-gas dispersion protection. These sections incorporate by reference NFPA 59A paragraph 2.2.3.2 (thermal radiation distance) and paragraphs 2.2.3.3 and 2.2.3.4 (vapor dispersion distance). NFPA 59A paragraph 2.2.3.7 is not provided as an alternative to §193.2057 and §193.2059 for permanent facilities.

Under §193.2019, mobile and temporary LNG facilities need not meet the requirements of Part 193 (including sections 193.2057 and 193.2059) if they comply with the applicable sections of NFPA 59A that is incorporated by reference. NFPA 59A paragraph 2.3.4 covers the requirements for such facilities. 2.3.4(g) references Table 2.2.4.1 for the spacing guidelines at mobile and temporary facilities. When table 2.2.4.1 is used for compliance with paragraph 2.3.4 (g), the aggregate capacity of the multiple LNG containers on the temporary site is to be used to determine facility spacing.

(D) Design

D1. What wind speed should be used in LNG facility equipment design calculations?

Wind forces are addressed in 49 CFR § 193.2067, which requires that LNG facilities be designed to withstand the direct effect of wind forces without loss of structural or functional integrity. Structural engineering design is typically performed using 3-second gust wind speeds in miles-per-hour (mph).

For shop fabricated containers of LNG or other hazardous fluids with a capacity of not more than 70,000 gallons, the wind forces at the location of the specific facility must be based on applicable wind load data in ASCE/SEI 7-05.

For all other LNG facilities, the wind forces at the location of the specific facility must be based on one of the following:

- an assumed sustained wind velocity of not less than 150 MPH; or

- a sustained wind velocity of less than 150 MPH that is justified by adequate supportive data and found acceptable by the Administrator; or

- the most critical combination of wind velocity and duration, with respect to the effect on the structure, having a probability of exceedance in a 50-year period of 0.5 percent or less, if adequate wind data are available and the probabilistic methodology is reliable.

For most structural engineering design calculations, the sustained wind velocity is converted to 3-second gust wind speed using a conservative method based on sound engineering principles. The Durst curve is an acceptable conversion method in ASCE/SEI 7-05, Chapter C6. Using this method, a sustained wind velocity of 150 mph is equivalent to a 183 mph 3-second gust. Applicants should also design all facilities to meet all applicable local or state building codes.

D2. To what parts of the facility does § 193.2067(b)(2) apply?

This paragraph applies to all LNG facilities other than those that are described in §193.2067(b)(1). The term "LNG facility" is defined in 49 CFR §193.2007. The parts of the LNG plant considered for compliance with this design requirement include all parts used when liquefying natural gas or transferring, storing, or vaporizing liquefied natural gas. This includes piping and any equipment, facility, or building used in the transportation of gas or in the treatment of gas during the course of transportation.

D3. Should the wind speed design criteria of 193.2067 be applied to vapor barriers at the LNG plant?

Since vapor barriers are installed for the purpose of reducing the extent of exclusion zones, they are a part of the LNG facilities and subject to the regulatory wind speed requirements. Vapor barriers must be functional while the LNG facility is in operation.

D4. Can vacuum jacketed piping be used in an LNG plant and may the outer pipe be used for LNG impoundment?

The applicant must fully document any application of vacuum jacketed pipe (VJP) or vacuum insulated pipe (VIP). The design details of the piping as well as the locations where it is to be used must be provided. In cases where the VJP or VIP may affect the prescribed design spills, impoundment determinations, or other hazard calculations, the applicant must fully justify the position and approach being taken. PHMSA will review these applications on a case-by-case basis, and a special permit (see 49 CFR Section 190.341) may be required.

D5. As an operator of a LNG Facility, our pressure vessels will be designed and fabricated to the current American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC). This differs from the requirements of 49 C.F.R. Part 193. How can I ensure our pressure vessels comply with Part 193?

To comply with the requirements of 49 C.F.R. Part 193, each applicant for a LNG facility designed after March 10, 2004, must do one of the following:

- Ensure compliance with NFPA 59A-2001, Paragraph 3.4.2, using the 1992 ASME BPVC; or,

- Submit an application for a special permit in accordance with 49 C.F.R. § 190.341; or,

- Demonstrate an equivalent level of safety as described in NFPA 59A-2001, Section 1.2.

Any deviation from the above requirements for pressure vessels by an operator of a LNG facility will require submittal of technical documentation for review by PHMSA on a case-by-case basis.

D6. As a design engineering firm or as an operator of a LNG facility, if our pressure vessels are designed and fabricated to the current American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC), which methods may I use to demonstrate safety equivalency as described in NFPA 59A-2001, Section 1.2, and as mentioned in FAQ D5?

Refer to NFPA 59A (2001), Section 1.2 Equivalency, which states:

Nothing in this standard is intended to prevent the use of systems, methods, or devices of equivalent or superior quality, strength, fire resistance, effectiveness, durability, and safety over those prescribed by this standard. Technical documentation shall be submitted to the authority having jurisdiction to demonstrate equivalency. The system, method, or device shall be approved for the intended purpose by the authority having jurisdiction.

When pressure vessels are designed and fabricated for use under Part 193 by using a more recent edition of the ASME BPVC than the 1992 version, the Operator is responsible to document the method used to determine equivalency and make this technical documentation available to PHMSA upon request. PHMSA will accept one of the following methods to demonstrate equivalency in accordance with NFPA 59A-2001, Section 1.2:

- Pressure vessels may be designed and fabricated to meet the requirements for test pressure and design margin factors found in the 1992 edition of the ASME BPVC; or,

- The maximum allowable working pressure (MAWP) for the pressure vessels may be reduced by the amount that results in a test pressure for all pressure vessels meeting the requirements in the 1992 edition of the ASME BPVC Section VIII, Division 1 or Division 2; or,

- Longitudinal, circumferential, nozzle-to-shell, tube sheet, header box, and nozzle-to-box header welds may be inspected by nondestructive examination (NDE). All longitudinal and circumferential welds and nozzle-to-shell welds for process nozzles six (6) inches or larger in diameter must be subject to 100% NDE. Accepted NDE methods are radiograph testing (RT), ultrasonic testing (UT), magnetic particle testing (MPT or MT), and dye penetrant testing (DPT or PT) along the entire weld length in accordance with the applicable sections of the current ASME Section VIII or other applicable standards. Longitudinal and circumferential welds must be subject to radiographic or ultrasonic testing; or,

- The operator of the LNG facility may develop, document, and implement a systematic approach, with annual inspections not to exceed 15-months, to ensure the long-term integrity of all its pressure vessels and pressure-relieving devices protecting these vessels within the LNG facility. The asset-management procedure must incorporate and comply with a current recognized and generally accepted American National Standards Institute (ANSI) standard such as the American Petroleum Institute (API) 510, "Pressure Vessel Inspection Code: In-service Inspection, Rating, Repair, and Alteration," 10th Edition. The procedures must be adopted into the operator's operations and maintenance (O&M) manual. The procedures must be updated, as needed, for the continuous, effective management of pressure vessel integrity that must include over pressure protection, corrosion, pipe wall thickness loss, cracking on both girth and longitudinal welds and steel body, loading stresses such as loads on nozzles from piping, valves, other components, and soil settlement and environmental deterioration of the pressure vessel due to weathering. Adoption and implementation of a pressure vessel asset management plan is in addition to the existing minimum requirements for operations, maintenance, and personnel qualifications and training found in 49 CFR Part 193 and NFPA 59A-2001. The operator must maintain all records and procedures for design, construction, testing, repairs, and O&M activities as required in API 510. The "Risk Based Inspection" option in Section 6.3 of API 510 is not an acceptable O&M inspection and evaluation method; or,

- The operator may submit to PHMSA another system, method, or device that is intended to demonstrate equivalency for evaluation and review on a case-by-case basis.

(DS) Design Spill Determination

DS1. The criteria and methodology used to identify single accidental leakage sources (SALS) to establish siting for my LNG facility were based on the failure rate table methodology. Do I need to submit a new or revised Design Spill Package to PHMSA based on the current SALS methodology?

No. PHMSA will not require the applicant to submit a new or revised Design Spill Package and will not retroactively apply the current SALS methodology to facilities that have received a previous PHMSA correspondence of no objection to their methodology for determining the SALS for design spills used in establishing the 49 CFR Part 193 siting requirements. If the applicant chooses to modify the design spills that were previously determined to be in compliance with Part 193 siting requirements, PHMSA will require an updated Design Spill Package as described in these FAQs. For those projects under FERC jurisdiction, the applicant will also need to file the updated information submitted to PHMSA on the FERC docket.

DS2. 49 CFR 193 requires that design spills for an LNG plant be selected according to NFPA 59A-2001 Paragraph 2.2.3.5. NFPA 59A requires the evaluation of accidental flow from "any single accidental leakage source" (SALS) but does not define this term. How should I select SALS events in an LNG plant?

For piping and equipment that handle LNG, flammable refrigerants, toxic components, and any other hazardous fluid, leakage sources may be chosen using the following guidelines. The SALS selection methodology, below, is applied to determine the maximum hole sizes of interest for the most significant releases of each hazardous fluid in each portion of the LNG plant. (The SALS selections are one component of design spill definition. Please refer to other FAQs for additional design spill definition topics.)

- For piping segments, including transfer arms and double-ply construction expansion bellows, that are:

- Greater than or equal to 6 inches in diameter, a hole of 2 inches in diameter is applied at any location along the piping segment; and

- Less than 6 inches in diameter, a full-bore rupture (guillotine failure) is applied at any location along the piping segment.

- For single-ply construction expansion bellows, a hole size equivalent to a full-bore rupture of the diameter of the expansion joint is applied;

- For pipe-in-pipe systems, an unobstructed release from an equivalent 1-inch diameter hole may be applied at the operating conditions of the inner pipe when:

- The system complies with NFPA 59A (2016) Section 9.11;

- The outer pipe is able to withstand the thermal shock, mechanical forces, and pressure loads of any single accidental leakage source from A and B above applied to the inner pipe; and

- Design, fabrication, examination, and testing of the pipe-in-pipe system, including calculations, can be demonstrated.

The selection of any alternate hole size or release scenario definition will be reviewed on a case-by-case basis in lieu of the criteria defined above; and

- For transfer hoses, a hole size equivalent to a full-bore rupture of the transfer hose is applied.

DS3. PHMSA reviews the design criteria for design spills on a case-by-case basis to determine compliance with Part 193. What information is required to assist PHMSA in its determination of the design spill criteria acceptable for use?

Applicants must provide a piping inventory table of LNG plant components in hazardous or flammable fluid service. At a minimum, the table should include piping of 2 inches in diameter and larger, as well as transfer hoses. The inventory table should be submitted in Excel (*.XL*) format. Separate tabs or lists should be used for each type of hazardous fluid, with demarcation of all of the final design spill selections. The table should include the following information:

- Line segment scenario number to identify the leakage source scenario;

- Description of line segment purpose (LNG rundown header, KO Drum drain, relief valve inlet, level gauge instrument connection, etc.);

- General plant area or service (e.g. liquefaction train, refrigerant storage, marine area, etc.), unless the entire project is confined to one area;

- Beginning point location (e.g., exchanger outlet flange) for each line;

- Ending point location (e.g., pump suction nozzle) for each line;

- Line diameter;

- Hazardous fluid service (LNG, natural gas, refrigerants (such as propane, ethane, mixed refrigerant), ammonia, natural gas liquids (NGL) or gas condensate, acid gas (containing hydrogen sulfide), etc.);

- P&ID drawing number reference(s) for each segment;

- Piping line designation on P&ID

- Fluid conditions within the line segment (e.g., fluid phase (liquid or vapor); density (lb/ft3); pressure (psig); temperature (°F); mass flow rate, (lb/hr); composition of mixed refrigerants, NGL/condensates, acid gas (mol%));

- Process flow diagram and corresponding heat and material balance stream number;

- Heat and material balance case selection;

- Leakage source hole size;

- Calculated total release flow rate (lb/hr);

- Calculated depressurization or equilibrium pressure used for release flow rate (psig);

- Release duration;

- For potential design spill selections, include release height, orientation, rainout percentage, total vapor mass flow rate (lb/hr), de-inventory duration, and screening dispersion distance (ft); and

- Comments, including any pump run out percentages used, as well as justifications or other details for the final design spills selected.

DS4. Is the largest size hole always used as the hole size in release modeling?

Not necessarily. For any defined maximum hole size, the applicant must demonstrate that that the hole size selected produces the greatest vapor dispersion distance when accounting for the mechanisms of flashing, jetting, aerosol formation, and rain-out. If a smaller hole size creates a larger vapor dispersion hazard distance, that smaller hole size should be used to define the design spill event. This applies to all single accidental leakage sources, including failures at piping, piping connections, and transfer hoses.

DS5. What are the proper release height and orientation to use for a design spill?

For each design spill identified, the release height should be the one that defines the largest hazard distances, bounded within the actual or anticipated heights of the equipment and piping.

Release orientation should be horizontal for each design spill unless a vertical orientation would produce higher consequences. Vertical orientations that provide higher consequences generally include:

- vertically upward for liquid releases with rainout greater than 25% (e.g., heavy hydrocarbons, pentane, etc.);

- vertically downward for gaseous releases (e.g., acid gas) ; and

- where mitigation measures would control or redirect the release, specific release orientations may be considered (e.g., pipe shrouding that directs a fluid downward, the downward direction may be applied).

A sensitivity analysis should be provided to demonstrate which release orientation scenario (horizontal, vertical upward, or vertical downward, as applicable) results in the largest hazard distance.

DS6. How are release locations defined?

For single-ply expansion joint or transfer hose failures, the release location can be identified at the specific point of that component in the LNG plant. For piping segments, the selected hole can occur at any location along the piping segment. If vapor barriers, shrouds, or pipe-in-pipe designs are used to reduce the vapor dispersion distance, locations potentially not impacted by the vapor barrier, shroud, or pipe-in-pipe should also be selected.

DS7. How do I determine the process conditions to evaluate for hazard modeling?

Process conditions should be based on heat and material balance modes of operation and design case

(e.g., rich, lean, average, etc.) that produce the worst case dispersion results from flashing and jetting and liquid releases. The leakage sources from branch connections should be considered using the potential operational conditions along the pipe as well as the potential operational conditions that could be experienced at or near the branch pipe connection to a main process line. In cases that would reduce the back pressure on pump(s) or compressor(s), the flow rates should consider the potential increased pump or compressor flow determined by the pump and compressor curve(s) as detailed in DS10 and also consider the decrease in temperature and pressure during runout conditions.

DS8. What considerations should be given to system inventory and spill duration in the design spill calculations?

The applicant may need to demonstrate the selected design spill duration. The release modeling should account for the available system inventory (including piping, process vessels, storage vessels, and other process equipment) when calculating the design spill duration as follows:

- Applicants may use a 10-minute spill duration if the process design includes acceptable detection, isolation, and shutdown.

- For long and large-bore piping with a significant distance between isolation valves (emergency shutdown or manually or remotely operated), as well as releases from process or storage vessels, the dispersion modeling may continue beyond the 10-minute design spill duration to account for the inventory volume in the piping and the entire contents of any vessels at maximum design level(s), unless the dispersion modeling endpoint reaches its furthest extent in a shorter time.

- A release duration of less than 10 minutes may be used for release scenarios where the available system inventory may be depleted in less than 10 minutes. The applicant may elect this shorter duration based on demonstrable surveillance, shutdown, and isolation design with valve closures from emergency shutdowns or remote valve operation per NFPA 59A-2001. All scenario isolation valves must be protected from failure, including fire and external impacts. The shutdown system must meet a safety integrity level (SIL) 2 or SIL3 reliability design and maintenance requirements in accordance with the International Society of Automation (ISA) 84 standards.

DS9. How should I consider a release from a process or storage vessel in the design spill calculations?

For systems with a process or storage vessel, the applicant should first select the appropriate release scenarios that account for the pipe flow (normal operational or pump run out) from the piping connecting to a vessel, based on FAQs DS7 and DS10. Furthermore, a comparative release scenario should be provided using the process or storage pressure from the vessel. This pressurized release rate may be calculated using the orifice equation at full operational system pressure, including the hydrostatic head from the maximum liquid design level, for the entire design spill duration. This corresponding duration would last until the inventory that could be isolated by valves would be depleted. The applicant should then perform a comparative screening to determine whether the piping or the vessel-pressurized scenario would result in the worst case dispersion distance.

Alternatively, transient flow scenarios may be evaluated to more precisely account for the effects of demonstrable surveillance, shutdown, and de-inventorying of the piping and vessel(s) on the release rate. A transient flow scenario should account for the most significant leakage source release from piping and the vessel, taking into account the normal flow into the vessel and the pressurized head space in the vessel.

DS10. Do I need to consider pump run-out in release scenario calculations?

Applicants should use pump run-out (greater flow than in normal pump flow operations) in failure calculations if the pump design allows increases in flow as the discharge pressure is reduced, unless acceptable preventive measures are used that prevent the pump from run out conditions. Pump runout parameters are presented by the pump manufacturer as a pump curve that shows flow increasing as the discharge pressure decreases. If pump run-out flows are not known at the time of submittal, engineering estimates may be employed provisionally.

Acceptable preventive measures include pump interlocks or safety instrumented prevention systems that meet safety integrity level (SIL) 2 or SIL3 reliability design and maintenance requirements in accordance with the International Society of Automation (ISA) 84 standards.

DS11. Should multiple pumps be considered when calculating the greatest flow from a spill to size impoundments or when defining a single accidental leakage source event?

Where the greatest flow is potentially fed from multiple pumps, calculate the flow to size impoundments assuming that all pumps are running, unless acceptable preventive measures are used that prevent all pumps from running concurrently.

Where a piping system utilizes multiple pumps, calculate the design spill based on the total flow from all system pumps running, unless acceptable preventive measures are used that prevent or limit all pumps from running concurrently.

Acceptable preventive measures include pump interlocks or safety instrumented prevention systems that meet safety integrity level (SIL) 2 or SIL 3 reliability design and maintenance requirements in accordance with the International Society of Automation (ISA) 84 standards.

(H) Hazards and Hazards Modeling

H1. Other than the flammable vapor dispersion and thermal radiation from hazards associated with LNG, what other hazards should be evaluated in the siting analysis for an LNG plant?

According to NFPA 59A-2001 Paragraph 2.1.1(d), (incorporated by reference in 49 CFR Part 193), all hazards that can affect the safety of the public or plant personnel are to be considered. In addition to LNG, the applicant should consider hazards associated with flammable gases, flammable refrigerants, flammable or combustible liquids, or acutely toxic materials. If present at the LNG plant, hazards including vapor dispersion from liquid pools, vapor dispersion from jetting and flashing phenomena, thermal radiation from pool fires, thermal radiation from fires involving jetting and flashing phenomena (jet fires), overpressure from vapor cloud ignitions, toxic gas dispersion, and boiling liquid expanding vapor explosions (BLEVEs) involving pressurized storage vessels should be included in an LNG plant's hazard evaluation.

H2. My LNG plant includes some toxic materials. What considerations should be given to accidental releases of these materials and the associated hazard modeling?

While the hazards associated with toxic substances at an LNG plant are not prescriptively covered in 49 CFR Part 193, their consideration is required by NFPA 59A-2001 Paragraph 2.1.1(d) (incorporated by reference in 49 CFR Part 193), which requires that all hazards that can affect the safety of the public or plant personnel be considered.

Many toxic substances stored above certain quantities are regulated under Appendix A of the EPA's "Risk Management Program for Chemical Accidental Release Prevention" (RMP, 40 CFR 68) and OSHA's "Process Safety Management of Highly Hazardous Chemicals" (PSM, 29 CFR 1910.119). Compliance with EPA's RMP and OSHA's PSM regulations is a sufficient approach to comply with NFPA 59A Paragraph 2.1.1(d). PHMSA does not have authority to enforce EPA or OSHA regulations, but requires operator compliance with NFPA 59A Paragraph 2.1.1(d).

Consideration of toxic hazards must include dispersion modeling appropriate for the toxic substance and its behavior upon release, as well as incorporating safety measures of the design and operation of the facility. Applicants may propose alternative modeling methods to comply with NFPA 59A Paragraph 2.1.1(d) for toxic substances. The release scenario selection methodology should be consistent with the selection methodology defined in FAQs DS2 and DS4 through DS11. In addition, the dispersion modeling should consider a method to account for the potential combined impacts of toxic components (e.g., the principle used in the Compressed Gas Association P-20 methodology). The AEGL values are the preferred endpoints to be used in the calculations with an exposure duration corresponding to the release event, up to 1 hour. Because there are no specific exclusion zones that are to be defined for toxic materials, the offsite impacts at each proposed LNG plant will be evaluated on a case-by-case basis.

H3. Materials received, stored, or used at my LNG plant could generate overpressures from a vapor cloud explosion. What considerations should be given to vapor cloud explosions and the associated hazard modeling?

While explosion overpressure is not prescriptively covered in 49 CFR Part 193, its consideration is required by NFPA 59A-2001 Paragraph 2.1.1(d) (incorporated by reference in 49 CFR Part 193), which requires that all hazards that can affect the safety of the public or plant personnel be considered. Vapor cloud explosion modeling should involve consideration of vapor dispersion modeling results, evaluation of areas of confinement and congestion, and the potential reactivity of released materials. The use of the 1.0 psi overpressure endpoint is appropriate for explosion modeling, and is consistent with the EPA's "Risk Management Program for Chemical Accidental Release Prevention" (RMP, 40 CFR 68). Because there are no specific exclusion zones that are to be defined for explosion overpressure impacts, the offsite impacts at each proposed LNG plant will be evaluated on a case-by-case basis.

H4. What wind direction should be used in exclusion zone and other hazard calculations?

For most hazard calculations, the exclusion distance or hazard distance is calculated independent of wind direction. If the wind direction is important in the modeling methods used, the direction used should be toward the nearest property line. Additional wind directions may also need to be analyzed if the hazard could extend beyond other property lines or cause other unique hazards.

H5. Can an exclusion zone extend beyond the operator's LNG plant property line?

As long as the facility is in operation, the operator is responsible for assuring compliance with the limitations on land use within exclusion zones, according to the descriptions in NFPA 59A Sections 2.2.3.2, 2.2.3.3, and 2.2.3.4. For example, an exclusion zone that extends past a property line into a navigable body of water or onto a public road is typically acceptable. This may not hold true if that body of water contains a dock or pier that is not controlled by the operator of the LNG plant, or if another entity could erect a building or members of the public could assemble within the exclusion zone. It is possible to assure compliance by legal agreement with a property owner affected by the exclusion zone, such that the land use is restricted for the life of the LNG plant.

H6. In addition to DEGADIS 2.1 and FEM3A, Section 193.2059 Flammable vapor dispersion protection provides for the use of alternate models approved by US DOT PHMSA. What other models have been approved?

On October 7, 2011, PHMSA approved two alternate models for the determination of vapor dispersion exclusion zones under 49 C.F.R. § 193.2059: FLACS 9.1 Release 2 and Phast versions 6.6 and 6.7. Each model has been validated for use in certain conditions in accordance with the Model Evaluation Protocol (MEP) as described in M. J. Ivings et al., Evaluating Vapor Dispersion Models for Safety Analysis of LNG Facilities Research Project: Technical Report (Apr. 2007) (available at http://www.nfpa.org under archived reports). The approval letters discuss the limitations for each modeling software.

On April 13, 2023, under 49 C.F.R. §§ 190.9 and 193.2059, PHMSA approved a petition requesting use of Phast version 8.4 (an updated version of Phast) as an additional model for calculating the vapor dispersion exclusion zones for Part 193-regulated LNG facilities. PHMSA evaluated the suitability of Phast version 8.4 using the process described in the 2nd edition of the Evaluating Vapor Dispersion Models for Safety Analysis of LNG Facilities (Ivings et al., 2016) (available at http://www.nfpa.org). PHMSA approves use of the Phast version 8.4 for calculation of the vapor dispersion exclusion zones only with the limitations described in the final environmental assessment and supplemental analysis conducted by Phast version 8.4's developer if the uncertainty factors are applied as described below:

- Phast version 8.4 may be used only with a minimum uncertainty factor of two as an alternate flammable vapor-gas dispersion model when computing flammable vapor dispersion distances to the lower flammable limit (LFL) (i.e., ½ LFL). This factor of two is based on Phast version 8.4's performance regarding the predicted distance to the LFL and ½ LFL. The vapor dispersion exclusion zones are the distances when the flammable vapor clouds reach the ½ LFL.

- Dispersion in stable conditions and at low wind speeds below 3 meters per second should be performed only with Pasquill stability class F.

- For dispersion over land, a surface roughness factor of 0.03 meters must be used in accordance with § 193.2059(b)(2). For dispersion over water where a surface roughness value is below 0.01 meters, an uncertainty factor of 2.5 must be applied to the distance at the LFL such that the vapor dispersion exclusion zones are 2.5 times the distances when the flammable vapor clouds reach the LFL.

For detailed information regarding the conditions for which the models were validated, see PHMSA's final decision at:

FLACS https://www.regulations.gov/search/docket?filter=PHMSA-2011-0101

Phast v6.6/6.7 https://www.regulations.gov/search/docket?filter=phmsa-2011-0075

Phast v8.4 https://www.regulations.gov/search?filter=phmsa-2021-0041

H7. Does US DOT PHMSA prescribe source term models for flammable vapor dispersion modeling?

While PHMSA does not prescribe or approve source term models, the source term model must have a creditable scientific basis and must not ignore any phenomena that can influence vapor formation during discharge from containment, conveyance to an impoundment, and retention within the impoundment. In July, 2010 PHMSA communicated in interpretation PI-10-0021 that the SOURCE5 model does not satisfy the PHMSA requirements for a source term model. The interpretation can be viewed at: https://www.phmsa.dot.gov/regulations/title49/interp/PI-10-0021.

H8. Can mitigation measures be used in exclusion zone and other hazard calculations?

For most hazard calculations, passive mitigation measures are inherently acceptable, provided that their design and implementation can be technically supported and that they do not introduce other harmful consequences.

Active or procedural mitigation measures are generally not included exclusion zone or hazard zone calculations. However, PHMSA will review the proposed inclusion of such measures on a case-by-case basis, provided that proper supporting technical justification and documentation is submitted.